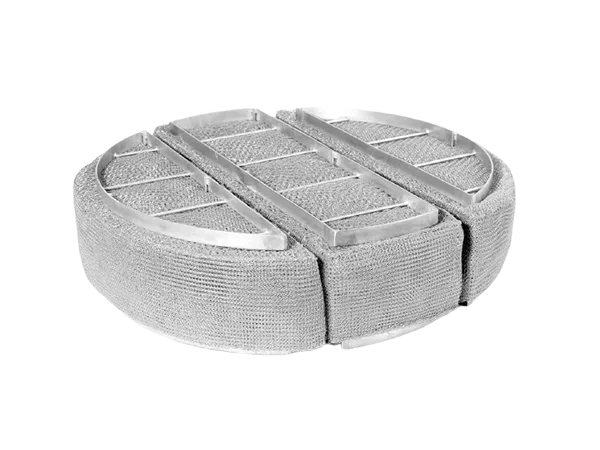

Mist eliminators consist of a pad of knitted wire mesh held between two rigid support grids. They efficiently remove liquid droplets from gas streams in various separation and demisting applications.

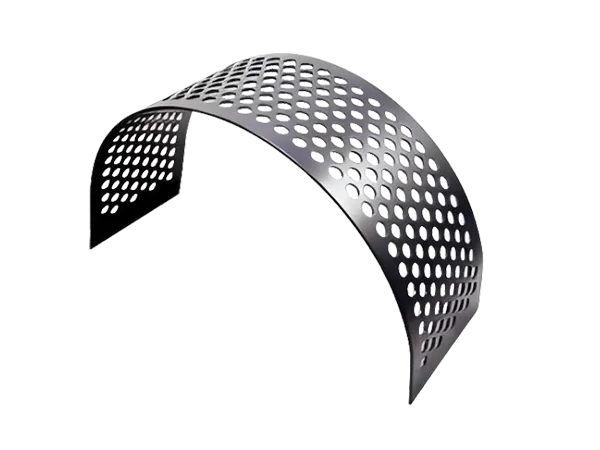

Perforated screens are commonly used as filter cylinders in oil filtration and other industrial screening processes, offering reliable mechanical strength and effective solid-liquid or solid-gas separation.

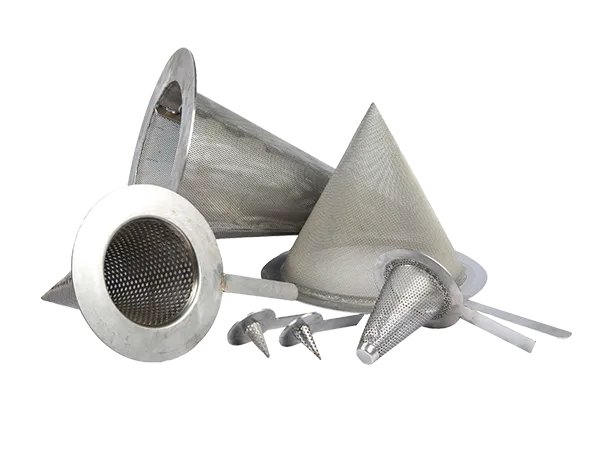

Temporary strainers are used during piping start-up to capture debris and protect downstream equipment. They work by channeling fluids through precision-sized openings for initial filtration.

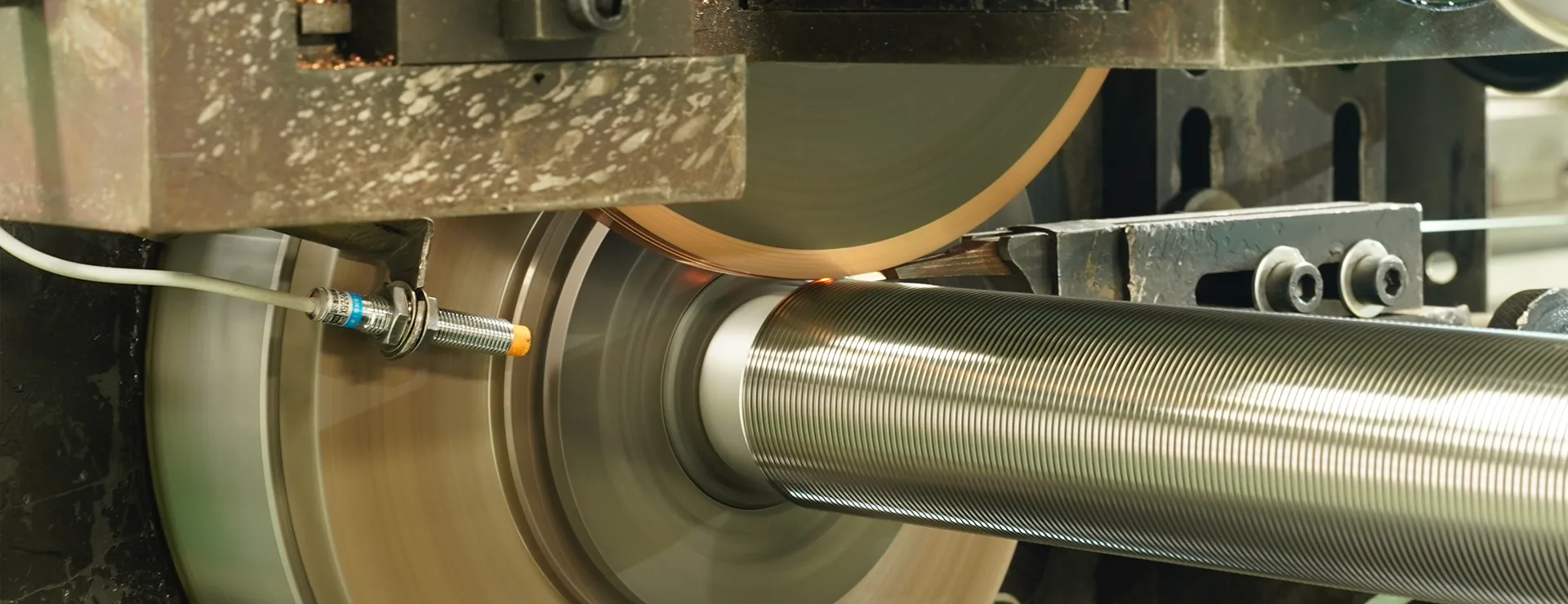

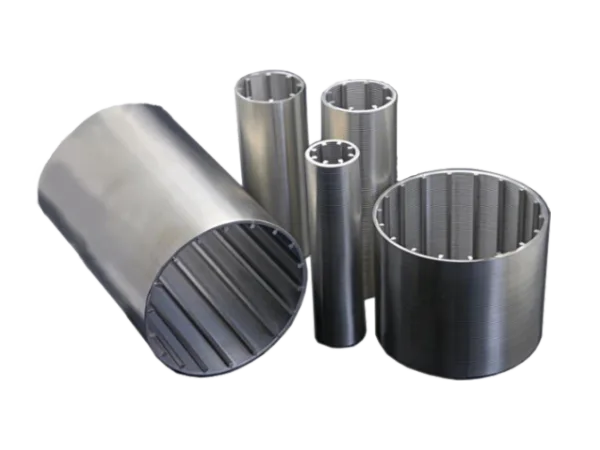

Wedge wire cylinders serve in rotary screens, water intake systems, resin traps, and strainers, ideal for applications requiring precise, durable liquid-solid separation in industrial and municipal processes.

Sieve bend screens are critical for slurry separation in starch production, providing high-capacity, low-maintenance performance by separating solids from liquids through curved screen surfaces.

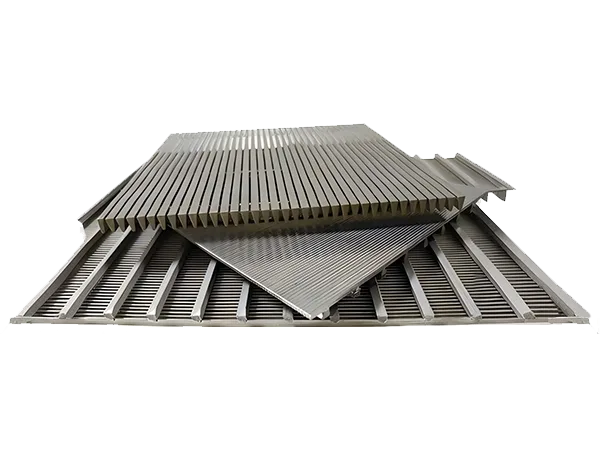

Wedge wire screen panels are widely applied in mineral processing, food production, and water treatment. They provide strong, non-clogging surfaces for efficient screening, filtering, and drainage.