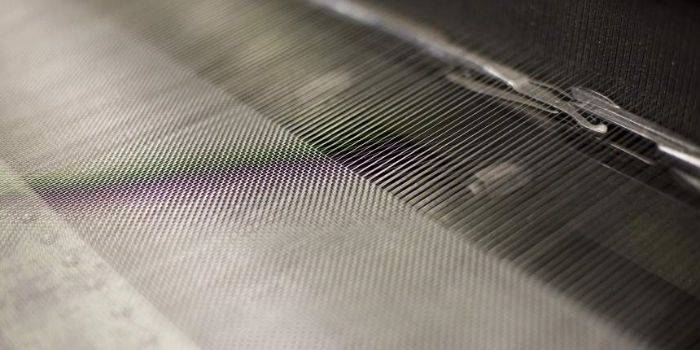

We adopt the most popular stainless steel 304, 316L and 430 as raw material and offer a full line of woven wire cloth and woven mesh products. Our weave types include plain weave, twill weave, plain Dutch weave and twill dutch weave. Of which, plain and twill woven wire mesh are the most economical and are often used for sifting and sizing, particle separation, filtering, safety, and security applications.

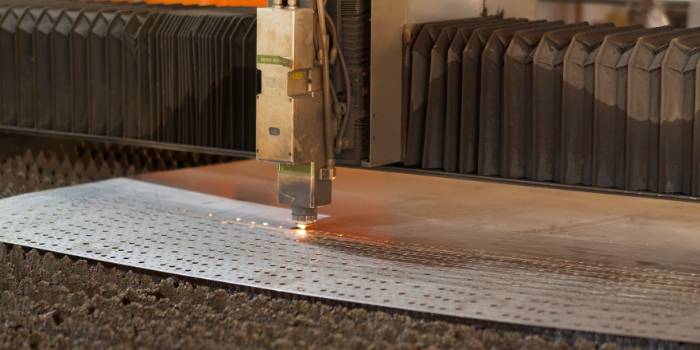

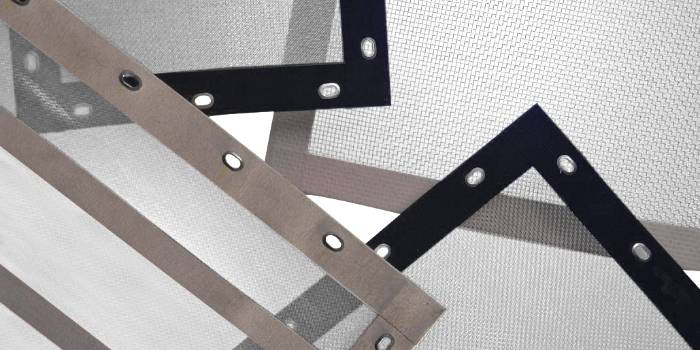

We have multiple cutting lines. We use different cutting technology to cut mesh panels/rolls into any desired shape and size according to their practical applications. Our advanced cutting technology enables us to provide our customers with large batches of metal filtration & separation products at a competitive price.

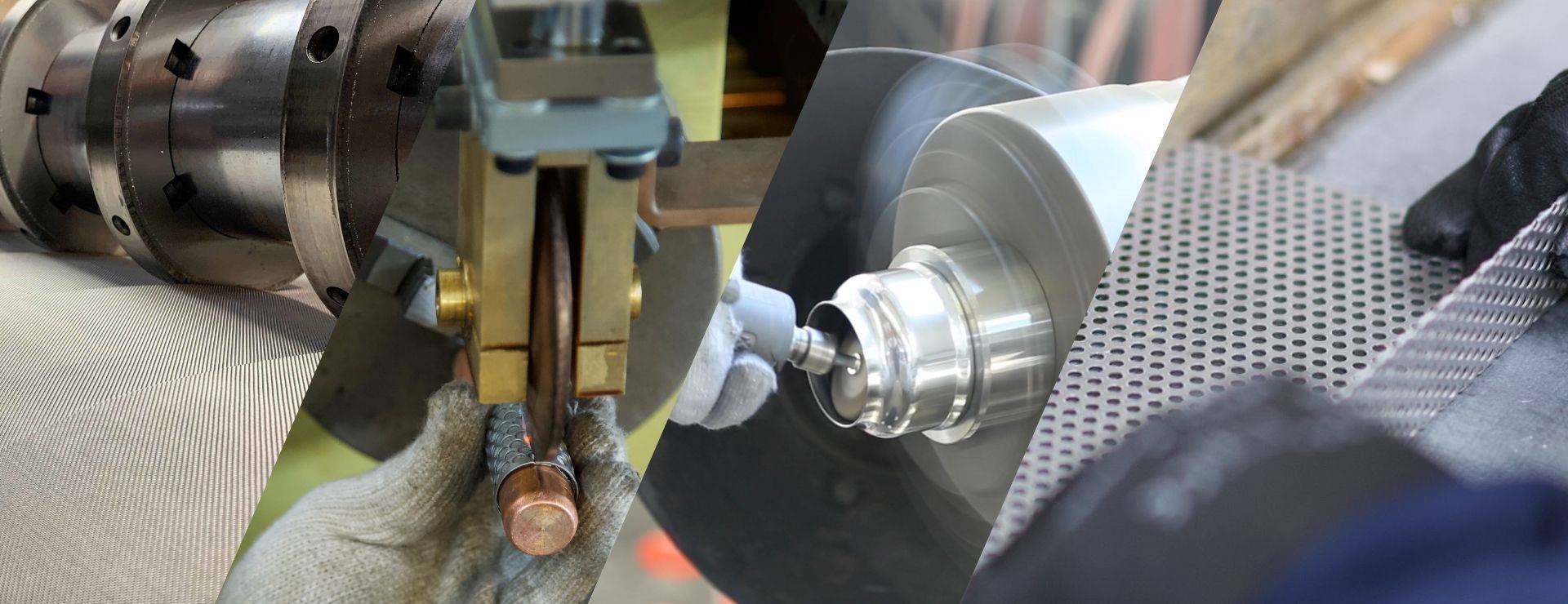

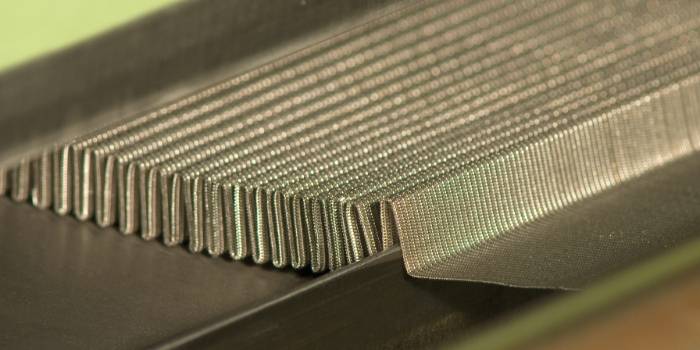

Our flexible forming & processing machines can produce filter elements of various shapes including cylindrical, conical, deep drawn or pleated.

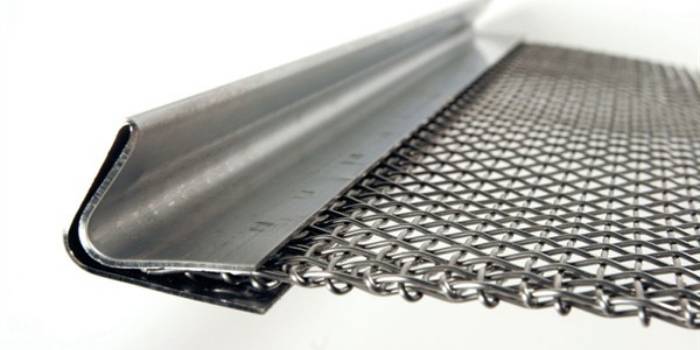

We have a broad range of welding devices and technologies. We will choose an appropriate welding method according to the material selected, thickness and weld seam shapes and try our best to provide best connection for every weldment and reliable, stable filtration & separation components for our customers.

We have a variety of surface treatment processes and can provide great coatings and finishes for finished products, thus enhancing the durability, aesthetic value and electrical performance of filter screens.