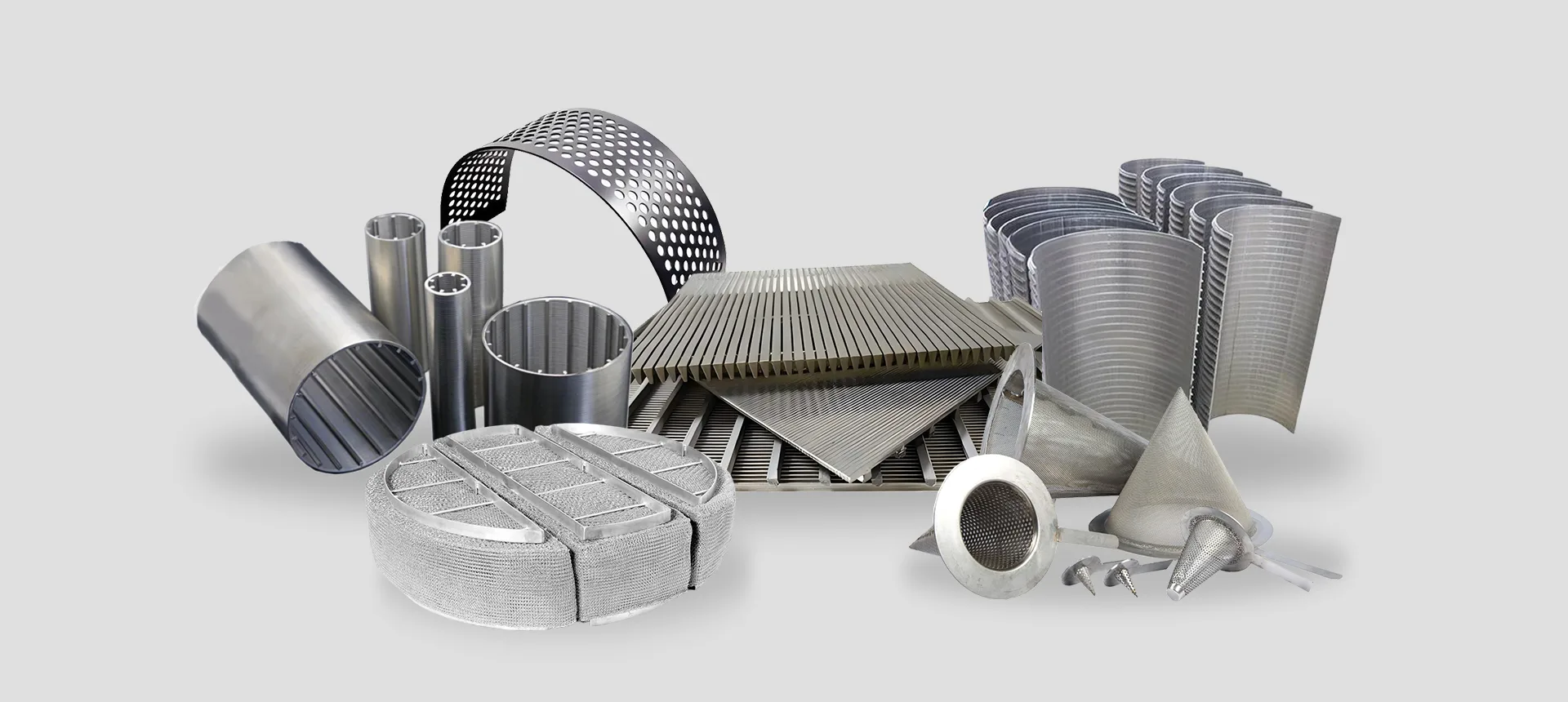

SUTON– Your Reliable Filtration & Separation Solution Partner

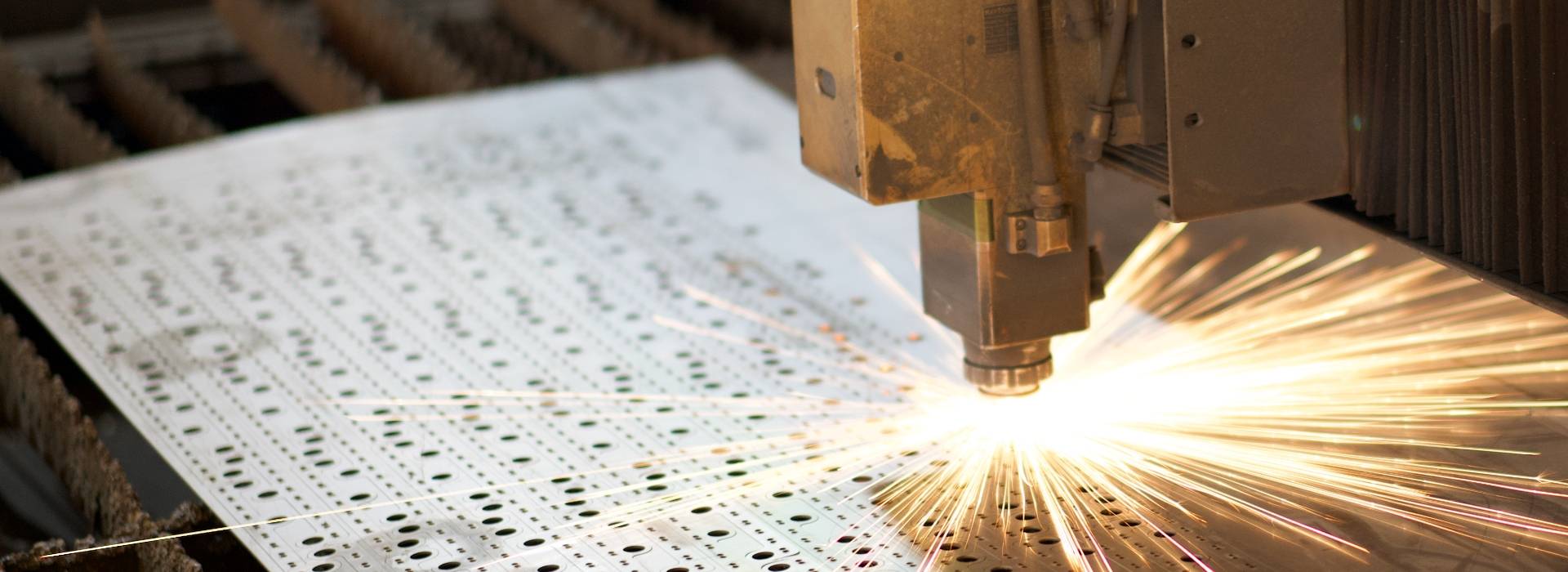

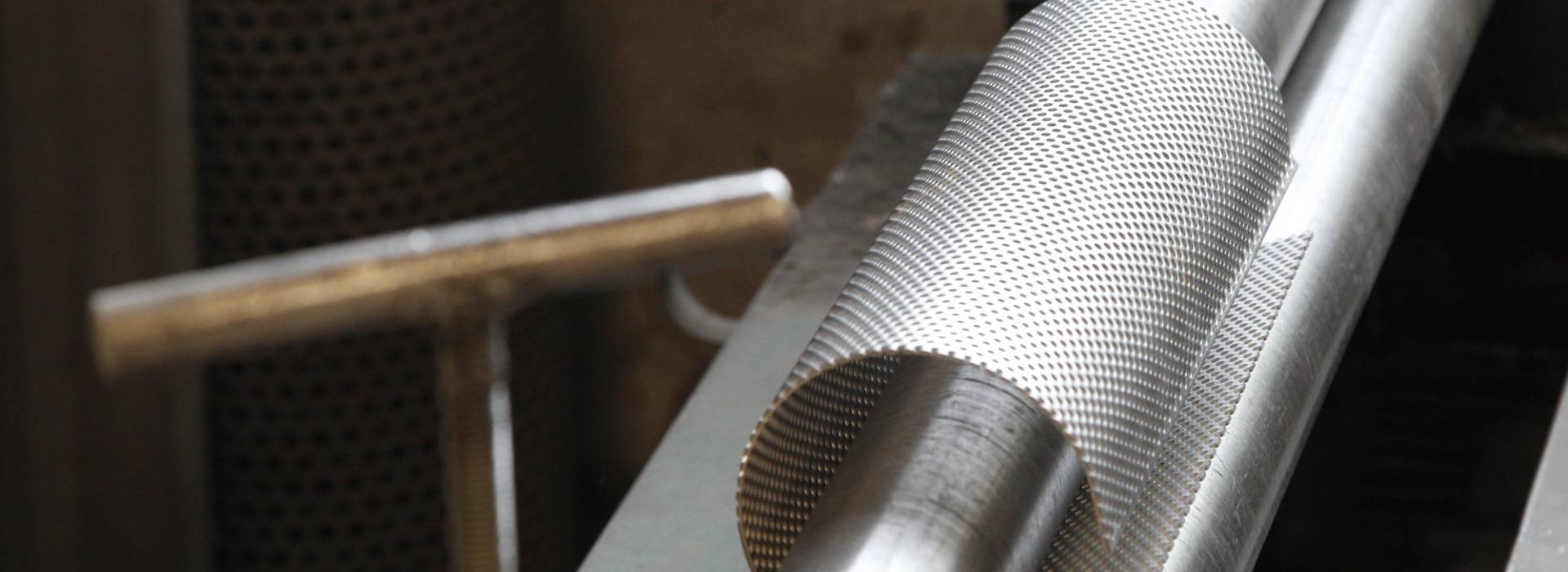

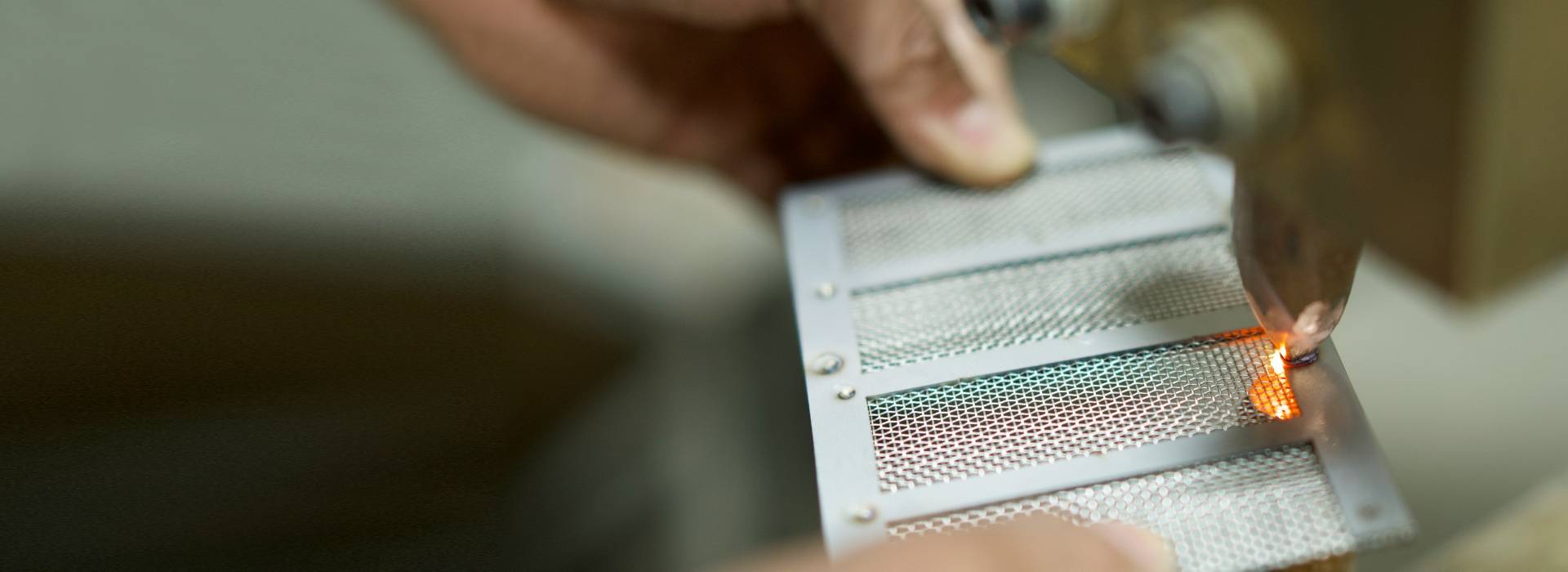

SUTON is an experienced filtration & separation solution provider with advanced processing machinery and equipment, high levels of expertise in metal materials and excellent R&D and design capabilities. At SUTON, we continue to provide our customers across the world with innovative, flexible and high-performance filtration & screening solutions.

Read More About SUTON +